Blog

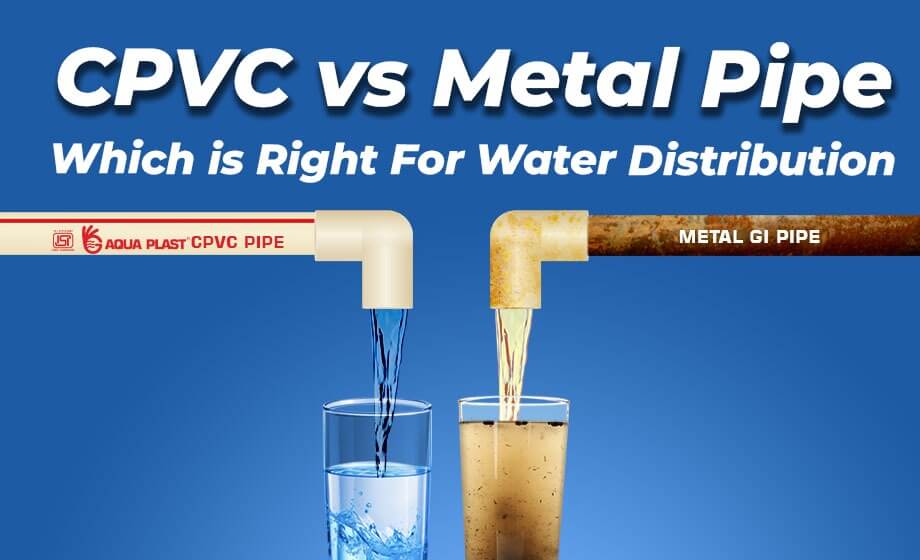

In the realm of water distribution systems for buildings, choosing the right material is crucial. CPVC (Chlorinated Polyvinyl Chloride) and metal are two widely used options, each with its set of advantages and considerations. Let's get into the details and understand the difference between two pipes. Additionally, a common question arises in this decision-making process: Is CPVC better than metal for your specific plumbing needs? We'll explore key factors to help you make an informed choice.

Introduction

When contemplating water distribution systems, the choice between cpvc vs metal pipe is pivotal. In this comparison, we aim to unravel the complexities and provide detailed insights into the suitability of CPVC and metal for water lines. Secondly we aim to address concerns related to safety, cost, and durability.

Which Pipe is Best for Drinking Water?- CPVC Vs Metal Pipe

The safety of the water we consume is paramount. Both CPVC and metal are deemed safe for carrying drinking water. CPVC is known for its resistance to corrosion, ensuring the water's quality, while metal pipes are considered durable.

The choice between cpvc and metal water lines depends on various factors, and both materials have their advantages and considerations.

Understanding the Differences with advantages and considerations

Here are some key points to help you make an informed decision:

Metal Pipes:

- Disadvantages :

Limited Heat Resistance: Metals, with the exception of certain alloys, are generally poor at resisting high temperatures. Instead, they conduct heat, making them prone to heat loss. This limitation can affect their suitability for hot water applications where heat retention is crucial.

Susceptibility to Corrosion: Metal pipes are prone to corrosion, which can compromise their integrity over time. Factors such as water quality and environmental conditions can accelerate corrosion, leading to leaks, blockages, and ultimately, the need for repairs or replacements.

Shorter Lifespan: Despite their perceived durability, metal pipes may not always have as long a lifespan as commonly believed. The susceptibility to corrosion and other forms of degradation can significantly reduce their longevity, often requiring replacement within decades rather than lasting for 50 years or more as commonly assumed.

- Considerations :

Cost: Metal pipes, especially copper, are generally more expensive.

Installation: Requires skilled labor, adding to the overall expense.

CPVC Pipes:

- Advantages :

Cost-Effective: These pipes are often more affordable than metal.

Lightweight: It is lightweight, making it easier to handle and install.

Chemical Resistance: CPVC pipe fittings are resistant to many chemicals found in water.

Easy Installation: These pipes are relatively easy to install and require less specialized labor.

- Considerations :

Temperature Limitations: CPVC pipes are designed for use in high-temperature environments, making them suitable for hot water applications such as near geysers. However, they have a temperature limit of 82 degrees Celsius, so they may not be suitable for extremely hot water applications exceeding this threshold.

Chemical Exposure (Hardness): CPVC pipes are suitable for household use where they come into contact with common tap water, as they are resistant to corrosion from typical water chemistry. However, they should not be used for conveying chemicals or substances other than potable water, as exposure to certain chemicals or extreme temperatures can weaken the material over time.

- Considerations for Both:

Water Quality: Consider the water quality in your area, as certain water conditions may affect the choice of material.

Is CPVC More Expensive Than Metal Pipes?

- Material Cost:

CPVC Pipes: CPVC pipes are generally less expensive than some metal pipes

Metal Pipes: The cost of metal pipes can vary widely based on the type of metal. Copper pipes, for example, are often more expensive than CPVC, while galvanized steel or black steel pipes may be more cost-competitive.

- Installation Cost:

CPVC Pipes: CPVC is lightweight and easy to install, which can reduce labor costs. Additionally, CPVC pipes can be joined using solvent cement, simplifying the installation process.

Metal Pipes: Some metal pipes, like copper, may require specialized skills for installation, and the process can be more time-consuming. Welding or soldering may be necessary for certain metal pipes, adding to installation costs.

- Long-Term Costs:

CPVC Pipes: CPVC pipes are resistant to corrosion, which can reduce maintenance costs over the long term. They also have a longer lifespan compared to some metal pipes that may corrode over time.

Metal Pipes: Depending on the type of metal, corrosion can be a concern. Corroded pipes may need to be replaced, leading to additional costs.

- Application Specifics:

CPVC Pipes: CPVC is often used for hot and cold water distribution in residential and commercial buildings.

Metal Pipes: Different metals are used for various applications.

In summary, CPVC pipes are generally considered cost-effective for certain applications, especially in water supply systems. However, the specific cost comparison with metal pipes will depend on factors such as the type of metal, local market conditions, and the requirements of the particular installation.

In the quest for both cost-effectiveness and quality, exploring reputable manufacturers like Gouri Aqua Plast becomes crucial. They deliver reliable and competitively priced pipes aligned with the need for durable yet budget-conscious solutions in the realm of plumbing. Considering such alternatives can contribute to a well-rounded decision-making process for your plumbing project.

Comparing CPVC and Metal Pipe Lifespan

Let's compare the lifespan of CPVC (Chlorinated Polyvinyl Chloride) pipes with that of metal pipes in general terms. Keep in mind that the lifespan of any plumbing material can be influenced by various factors, including water quality, installation practices, and environmental conditions.

- CPVC Pipes:

Lifespan: CPVC pipe are also durable and on average, CPVC pipes can last between 25 to 50 years.

Chemical Resistance: It's important to note that CPVC pipes have a temperature limit of 82 degrees Celsius, and exposure to temperatures higher than this threshold can compromise their integrity.

Potential for Brittleness: Over time, CPVC pipes may become brittle, especially when exposed to certain chemicals or high temperatures. This can impact their long-term durability.

Installation: Proper installation is crucial for ensuring the longevity of CPVC pipes. If not installed properly, it can affect their performance and lifespan over time.

- Metal Pipes:

The lifespan of metal pipes can vary depending on the type of metal used. Common metals used in plumbing include steel, copper, and galvanized steel.

Steel Pipes: Depending on factors such as water quality and environmental conditions, steel pipes can have a lifespan ranging from 20 to 50 years. Corrosion is a potential concern for steel pipes.

Copper Pipes: Copper pipes are durable and corrosion-resistant, with a lifespan of 50 to 70 years or more under normal conditions. It was widely used for water supply lines but due to its cost it is nowadays getting replaced with CPVC pipes.

- Factors Influencing Lifespan:

Water Quality: The quality of the water being transported through the pipes can impact their lifespan. Metal pipes, especially steel, can be more susceptible to corrosion in certain water conditions.

Installation Practices: Proper installation techniques, including appropriate supports, fittings, and connections, are crucial for the longevity of both CPVC and metal pipes.

Corrosion Resistance: CPVC is inherently resistant to corrosion, while certain metals, like steel, may require additional measures (such as coatings) to mitigate corrosion.

- Maintenance:

CPVC typically requires less maintenance compared to metal pipes. Metal pipes may need periodic inspections for signs of corrosion, and corrective measures may be necessary. When considering CPVC pipes, it's essential to choose reliable products from reputable pipe manufacturers. Gouri Aqua Plast, a well-established cpvc pipe manufacturers, is known for delivering high-quality CPVC pipe.

They adhere to stringent manufacturing standards, ensuring durability and long-term performance of their products. Choosing a trusted manufacturer can provide assurance of product quality and reliability in your plumbing systems.

- Cost Considerations:

CPVC pipes are generally more cost-effective than certain metal pipes, such as copper. The cost difference can be a factor in the decision-making process for some projects.

It's essential to note that the lifespan of plumbing materials is a general estimate, and actual results may vary based on specific conditions. Regular maintenance and periodic inspections can help identify issues and ensure the longevity of the plumbing system, regardless of the material used. Ultimately, the choice between metal and CPVC should consider factors such as cost and the specific requirements of the plumbing application.

As you compare the considerations between metal and CPVC, it's worth exploring reliable alternatives such as Aqua Plast CPVC pipes. Their dedication to high-quality manufacturing processes and adherence to industry standards make their pipes a promising option for those seeking a durable and cost-effective solution. Factor in such alternatives when making your decision, considering not only the immediate cost but also the long-term performance of the chosen plumbing material for your specific application.